Each plan is custom-made based on the pool’s size, shape, and specifications.

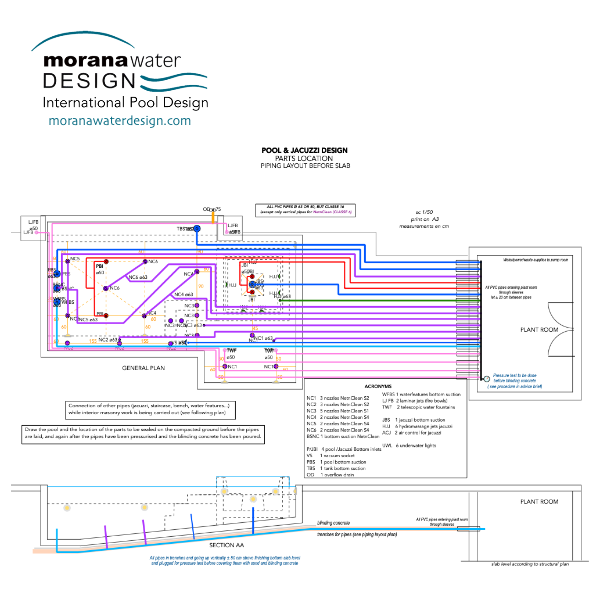

We design the piping layout based on the original plan drawn by the customer’s architect or our team.The details of the plan, such as the size, type, and grade of the pipes, are all taken into consideration for the highest possible performance.

A filtration flow rate is determined by the size of the pool and the type and length of overflow.

The drawing shows precisely where each part, pipe or fitting has to be placed. This precise placement of the pipes is crucial to ensure the ideal filtration flow rate is achieved and the water is directed through the filter at the optimal speed for the most efficient filtration.

Creating hydraulic plans for a pool requires specific technical expertise that cannot be provided by automated online solutions.

This expertise can only be acquired through professional training, making the process of creating a successful plan more complicated and time-consuming. Furthermore, we have extensive knowledge of the various options and configurations available for overflow pool plumbing systems.

The answer is twofold: most pool builders don’t possess engineering expertise, and they don’t need drawings. Why not? Since the same filtration scheme is used every time, there is no need for detailed drawings. The pool builders know the general rules and regulations of pool construction and that, together with the experience of the workers, makes engineering expertise unnecessary. In addition, skimmer pools, which are the majority of pools, have fewer pipes and only have a filter and a pump.

Pool piping ensures that water can flow freely from the pool to the filtration system and back, thus allowing the pool to be maintained in an efficient and effective manner.

Overflow pools piping network create a closed circuit. This ensures that the pool can be kept clean and efficient without having to constantly add and remove water.

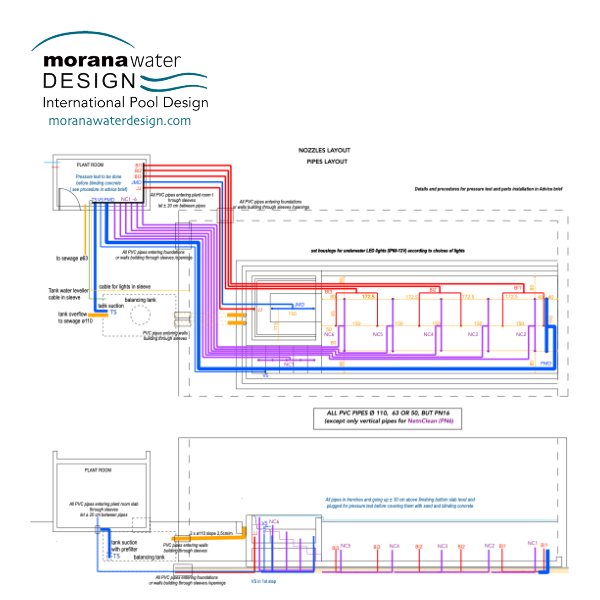

The first step is calculating the filtration flow rate based on the volume of the pool and the type and length of overflow; from this, we determine the number and positioning of the return inlets to ensure an even distribution of water throughout the pool. Although the cleaning robot tends to replace manual pool cleaners, we always install a vacuum socket; you never know!

Using the ground plan, we draw each pipe and each part that needs sealing. Drawing the pipes and parts accurately is crucial – mistakes can have serious consequences. To make this process easier, we use different colors to distinguish between suction and discharge networks.

By providing the dimensions of the connecting pipes and tees, installers can better understand the flow of water. This will enable them to ensure that each nozzle receives the same amount of water pressure, allowing for a more efficient, balanced system.

The measurements can be easily transferred to the walls or bottom of the pool, which makes the installation process even simpler. Of course, the layout of the pipes considers the position of the pump room in relation to the pool.

Pipes connected to parts embedded in the walls are shown in a section of the pool. Same with underwater lights, whose locations are clearly marked.

Choosing customized plans during the design or renovation of a pool is a wise decision for many homeowners. It not only ensures that the pool blends seamlessly with the existing environment, but also guarantees optimal space utilization and maximum efficiency of the facilities.

Our pool-to-technical-room connection plans are designed to allow installation by plumbers without pool experience, or even by DIY enthusiasts. Many of our clients have been pleased to actively participate in the construction of their pool by handling the hydraulic part themselves.

The design of the piping aims to give the owner the freedom to choose the installer: pool specialist, general plumber, craftsman, etc. All solutions are possible. The ultimate goal is, of course, to negotiate the best installation for the pool’s filtration system, resulting in significant savings.

We would also add that having precise plans of the fluid network can always prove useful. If they wish, owners have the information to purchase the necessary equipment themselves.

The next obvious step is to map out a clear plan for the pump room. Starting with the building plan and continuing with the connection plan, we draw the installation of the plant room:

WhatsApp Messaging only

French expertise in infinity pool design, based in Ireland and trusted by clients around the world.

©2023 Morana